Palantir Automotive and Mobility is helping OEMs, suppliers, and dealers turn the corner on automotive quality

The automotive industry is facing some of its biggest challenges yet.

Inflation is driving the cost of raw materials up while compounding supply chain disruptions are leading to component shortages. The war in Ukraine threatens gas supplies and contributes to an unstable global economy, while across Asia, plant shutdowns are stalling production and increasing build costs.

Consumer preferences and demand are also changing in unprecedented ways in response to cultural and mobility changes brought about by COVID-19, climate change, and electrification. As a consequence, today’s cars are increasingly software-driven and complex, with newer supply chains and more parts and available configurations than ever before.

All of these conditions have been especially disruptive for automotive quality, a key driver of customer loyalty during unpredictable economic times. J.D. Power’s 2022 Initial Quality Study delivered alarming news: vehicle quality problems hiked by a record 11% year-over-year, bucking a long-running trend towards improved quality. In 2022, new models were four times as likely to perform worse than their segment averages than they were to perform better, with battery-electric vehicles and plug-in hybrid vehicles underperforming when compared to cars with internal combustion engines.

It’s not uncommon for automakers to spend over $1 billion per year on total warranty spend. But despite receiving terabytes of field quality data from connected vehicles, automotive companies often lack the tools to make this data usable for warranty analytics and cross-company quality management. Automakers, suppliers, and dealers need to act now in order to proactively address issues before they happen in the field and turn the corner on quality.

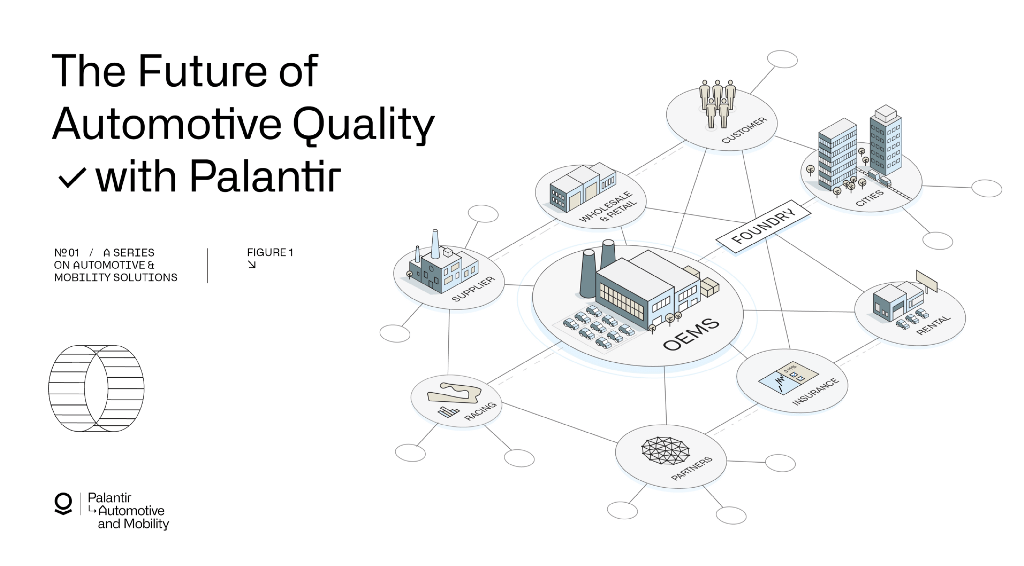

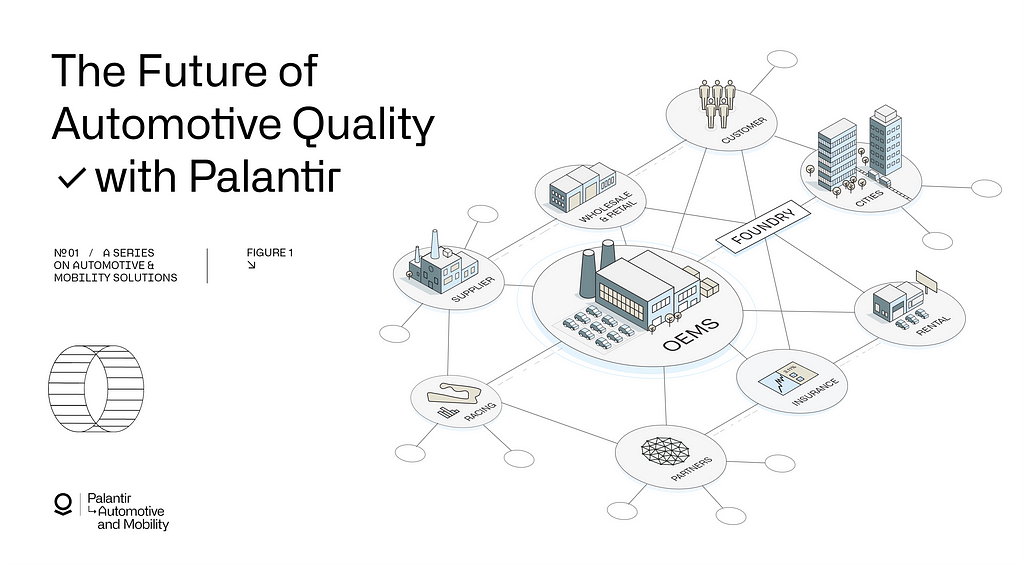

Palantir Automotive & Mobility is meeting these challenges through the power of the Foundry platform.

Our latest Automotive and Mobility solutions reflect years of development knowledge gleaned from some of the top OEMs and suppliers in the world, and they are forming the building blocks for new economies of scale using data. With the Foundry platform, companies can operationalize their data to solve problems across the automotive value chain. They can also leverage any of the pre-built modules below to meet their most pressing challenges within weeks.

Introducing the Palantir Quality Management OS

Foundry’s Quality Management OS (QMOS) is an end-to-end quality solution for OEMs. It integrates relevant data from suppliers and dealers, diagnostic trouble codes, connected vehicle telematics, warranty claims, and more to provide a holistic view of quality.

With QMOS, our customers are able to detect issues faster and reduce time between issue detection and measure implementation. By doing so, they can mitigate the cost of expensive recalls, leading to major savings.

The Component Performance Monitor (CPM): An New Industry Standard for Supplier x OEM collaboration

Palantir Component Performance Monitor, or CPM, is the cornerstone enabler of OEM and supplier collaboration in Palantir Foundry. CPM gives suppliers access to real-world data, so suppliers can see how their products perform and respond accordingly while collaborating with the OEM to proactively pinpoint field and manufacturing issues before they lead to failures or customer dissatisfaction.

Leading suppliers such as Valeo and ZF are collaborating with their OEM counterparts under a shared data fabric using CPM and pioneering the future of automotive quality by uncovering new opportunities to generate value through data. Find out more about what we are building together by reading our in-depth whitepaper.

Using CPM, a supplier was able to identify vehicles at risk of a serious quality issue by analyzing large scale field data in Palantir CPM. With less than 1% of the whole population affected, a costly warranty extension was avoided and millions in quality costs prevented. One component team implemented countermeasures 3 months faster by using the CPM to monitor live field data and detect new error patterns.

Palantir Technologies is committed to transitioning CPM into the Catena-X marketplace. Catena-X is the first integrated, collaborative, open data ecosystem for the automotive industry, launched in 2021 with support from the German Federal Ministry for Economic Affairs and Energy. Learn more about our CPM partners and our work towards building a connected automotive industry in our whitepaper: Enabling Greater OEM and Supplier Collaboration for Automotive Quality.

More Solutions Across the Automotive Value-Chain

QMOS and CPM can help mitigate the cost of expensive warranty campaigns, leading to immense savings. However, they are just a sample of the many automotive solutions developed by Palantir:

Manage unexpected shocks in the supply chain with a transparent digital twin of your global supply chain that proactively shows potential problems like plant shutdowns, production bottlenecks, and logistical delays. Apply complex “what-if” scenario analysis on this data asset to dynamically choose an optimal procurement and distribution strategy.

Foundry’s Plant Digital Twin enables manufacturing teams to optimize production with an integrated feedback loop, leading to decreased re-work, improved in-field performance, and quicker turnaround times for critical investigations. It can help react to unforeseen production changes and supply chain disruptions without sacrificing the commitment to quality and safety.

Foundry can help understand customer configuration demand to reduce the complexity of available vehicle configurations. Meet the challenges of rising costs per vehicle by fusing data integration and analytics with operational decision-making tools.

Reducing material costs is key to staying competitive in today’s automotive market. Foundry can integrate data — such as composition supplier contracts, historical and forecasted raw material prices, production volumes, and more — to help identify and select COGs reduction strategies.

Palantir Foundry is built to help large organizations react to critical, time-sensitive work. From empowering smooth production ramp-ups to optimizing sales campaigns and monitoring initial in-service performance, data is at the core of ensuring the success of a new vehicle launch.

Achieve an accurate and transparent accounting of CO2 contributions from your entire supply chain: from processing raw materials to in-service use, including part and vehicle distribution. Develop a carbon cost reduction roadmap and test “what-if” scenarios to determine your best strategy for reaching net zero.

Palantir Connected Customer is a platform where OEMs can collaborate with their dealerships on parts management, service schedule optimization, and marketing — all while protecting privacy and ensuring appropriate handling of sensitive data.

A Connected Industry

Today, the automotive industry is at the epicenter of a new data-driven industrial revolution — and Palantir and its customers are leading the charge.

Automotive companies are using Palantir’s foundational software for the modern enterprise, Foundry, to develop game-changing workflows that are delivering impact in R&D departments, assembly lines, and dealerships. But we are going further: creating a foundational fabric for shared growth and collaboration across the industry.

To learn more about Palantir’s Automotive and Mobility solutions, visit our website.

How Palantir’s Automotive Solutions Will Revolutionize Quality was originally published in Palantir Blog on Medium, where people are continuing the conversation by highlighting and responding to this story.